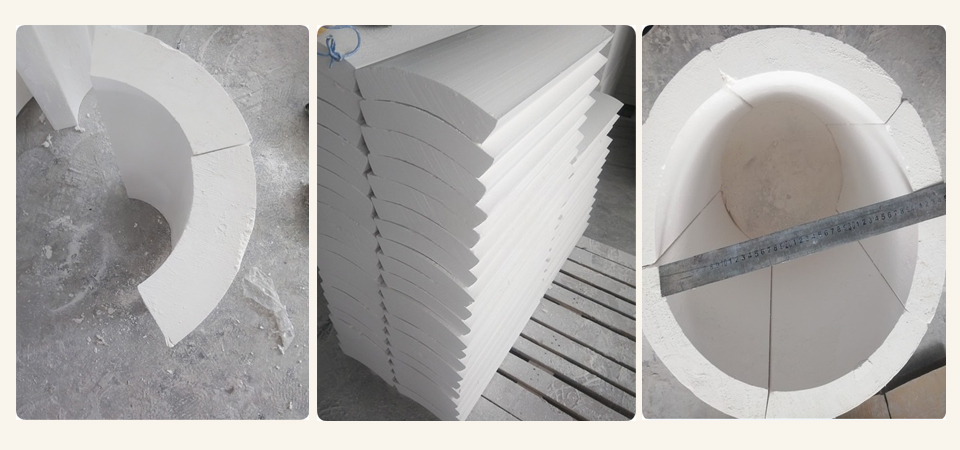

Product Overview: Calcium Silicate Pipe Shell

Our 1000°C High-Temperature Calcium Silicate Pipe Shell is a specialized insulation material designed for extreme thermal resistance in various industrial applications. Made from high-quality calcium silicate, it provides superior thermal insulation properties, making it ideal for high-temperature environments where maintaining heat is essential. The product is available in both standard and customized shapes, and features 650 micropores to further enhance its insulation performance.

In addition to its thermal insulation capabilities, our calcium silicate pipe shells are hydrophobic, ensuring effective moisture resistance. We specialize in the production and customization of high-temperature calcium silicate materials, offering tailored solutions based on specific customer requirements and drawings.

Key Features:

Temperature Resistance: Withstanding temperatures up to 1000°C (1832°F) for high-performance heat insulation.

650 Micropores: Offers enhanced insulation properties, reducing heat loss and improving energy efficiency.

Hydrophobic Properties: The hydrophobic design ensures water resistance, preventing moisture damage and improving durability.

Customizable: We offer customized sizes and shapes, allowing you to meet specific industrial insulation needs.

Non-toxic and Safe: Made with asbestos-free materials, ensuring safety during installation and use.

Lightweight: Easy to handle and install, reducing labor costs and simplifying the installation process.

Durable: Resistant to chemical corrosion, thermal shock, and physical wear, providing long-lasting performance.

Versatile: Available in different forms, such as block, pipe shell, or custom-shape, to meet various industrial needs.

Applications:

Cement Industry: Provides insulation for cement kilns and other high-temperature equipment, reducing heat loss and improving energy efficiency.

Glass Industry: Used for high-temperature insulation in glass furnaces and melting kilns to retain heat and prevent energy wastage.

Non-ferrous Metal Industry: Ideal for reducing heat loss in furnaces used in the processing of non-ferrous metals.

Aluminum Industry: Used in high-density, non-stick calcium silicate boards for thermal insulation, preventing aluminum from sticking to the insulation material.

Power Generation: Insulation for boilers and other power plant equipment, helping to maintain operational efficiency and reduce energy consumption.

Custom Industrial Applications: We offer customized solutions for a variety of high-temperature applications, such as heat shields, refractory linings, and more.

| Item | Unit | KF-250 | Test Results (Average) |

|---|---|---|---|

| Density | kg/m³ | 250+10% | 249 |

| Tensile Strength | MPa | ≥0.35 | 0.37 |

| Compressive Strength | MPa | ≥0.35 | 0.37 |

| Thermal Conductivity | W/(m·K) | ≤0.055 | 0.054 |

| Usage Temperature | °C | 1050 | 1050 |

| Linear Shrinkage | % | ≤2 | 1.48 |

| Surface Water Content | % | ≥98% | 99.3% |

| SiO₂ | % | - | 99.3 |

| CaO | % | - | 45.1 |

| Fe₂O₃ | % | - | 0.26 |

| Al₂O₃ | % | - | 1.03 |

| Loss | % | - | 6.4 |