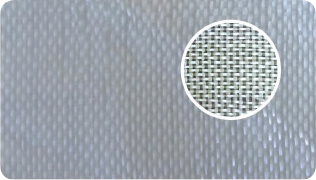

Colored Fiberglass Fabric

| Product Description |

Colored fiberglass fabric is treated with special coatings and dyes to cover the surface of the glass fiber, which helps to stabilize the weave pattern, reduce fuzzing, and create a cleaner fabric appearance. It also improves wear resistance and cutting performance. Depending on the dye used, it can significantly enhance the fabric’s resistance to oil, solvents, and chemicals. |

|---|---|

| Product Features | 1. Excellent chemical resistance, withstands acid, alkali, saltwater, and various organic solvents. 2. Low coefficient of friction, ideal for applications requiring lubrication-free performance. 3. Excellent UV resistance and low static generation. 4. High strength, good mechanical performance. 5. Protects underlying steel surfaces while enhancing product appearance. |

| Applications | Colored fiberglass fabric is widely used in shipbuilding, containers, cold storage, vessels, vehicles, trenches, and architectural materials. |

Medium Alkali Fiberglass Fabric

| Product Description |

Medium alkali fiberglass fabric is made from alkali metal silicate glass fiber yarns. The content of metal oxide in the fabric is approximately 12% ± 0.4%. |

|---|---|

| Product Features | 1. The fabric surface is flat, with good transparency, and easy to handle. 2. The yarn arrangement is uniform, with high dimensional stability and low fiber fuzzing. 3. Excellent compatibility with a variety of resins, improving interfacial bonding strength. 4. Strong design adaptability, easy to sew and laminate. |

| Applications | Suitable for making fiberglass base materials, surface coating fabrics, oil-resistant base cloths, wind blade reinforcements, composite packaging materials, bonding substrates, acid-base filtration fabrics, reinforcing nets, and various insulation products. |

| Specifications | Common models: 01/015/018/02/04 120G/m², 125G/m², 135G/m², 200G/m², 300G/m², 330G/m², 400G/m² |

| Packing | 50–150 meters per roll, customizable based on customer requirements. |

| Storage | Store the product in a dry, cool, and ventilated area. Avoid rain exposure. Recommended storage conditions: temperature 5°C–35°C, humidity 35%–65%. Leave at room temperature for more than 24 hours before use for better performance. Suggested to use within 12 months after receipt. If unused, avoid opening the packaging or loosening the wrap to prevent moisture absorption. |

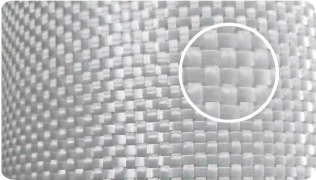

Alkali-Free Fiberglass Fabric

| Product Description |

Alkali-Free fiberglass fabric is made from alumino-borosilicate glass fiber yarns, with a metal oxide content not exceeding 0.5%. |

|---|---|

| Product Features | 1. The fabric surface is flat, has excellent transparency, and is easy to handle. 2. Uniform yarn distribution, excellent fiber bundle integrity, low fuzz. 3. Effectively improves fatigue resistance and crack resistance of composite materials. 4. Excellent design adaptability, easy to sew and laminate. |

| Applications | Suitable for use in high-grade electrical insulation base materials, as well as reinforcing materials in epoxy board substrates. It can also be used in the production of circuit boards, structural materials, aviation equipment, and other large composite parts and equipment. |

| Specifications | Common product models: 01/02/03/04/06/08 100g/m², 200g/m², 300g/m², 400g/m², 500g/m², 600g/m², 800g/m², 1000g/m² |

| Packing | Each roll is packed in plastic film, 100 meters per roll. Customized packaging available upon request. |

| Storage | Store the product in a dry, cool, and ventilated area. Avoid rain and moisture. Recommended storage conditions: temperature 5°C–35°C, humidity 35%–65%. Leave at room temperature for more than 24 hours before use for optimal performance. Suggested to use within 12 months. If not used, avoid opening or loosening packaging to prevent moisture absorption. |

| Note | The width range for E-glass fiberglass fabric products is 100mm–2700mm, and can be customized according to special customer requirements. |

Glass Fiber 04 Fabric

| Product Description |

Glass Fiber 04 fabric is a high-performance inorganic non-metallic material. It is made from glass fiber or raw glass yarns through processes such as weaving or knitting. It is commonly used as a reinforcing material in composites, thermal insulation in electrical insulation materials, and circuit board substrates. |

|---|---|

| Product Features | Corrosion-resistant, does not rot underground, does not oxidize in air, waterproof, and resistant to insects. |

| Applications | Mainly used for anti-corrosion, thermal insulation, and fire prevention in pipelines. Also suitable for hand-laid fiberglass crafts. |

| Specifications | Available weights: 300g/m², 330g/m², 400g/m² |

| Packing | Each roll is packed in plastic film or woven bag. |

| Storage | Store in a dry and cool place, protected from rain and humidity. Recommended storage temperature: 5°C–35°C, humidity: 35%–65%. Place at room temperature for at least 24 hours before use for optimal results. Recommended to use within 12 months. If unused, avoid opening the packaging or loosening it to prevent moisture absorption. |